Fogwing Matrix – Smart Production Monitoring

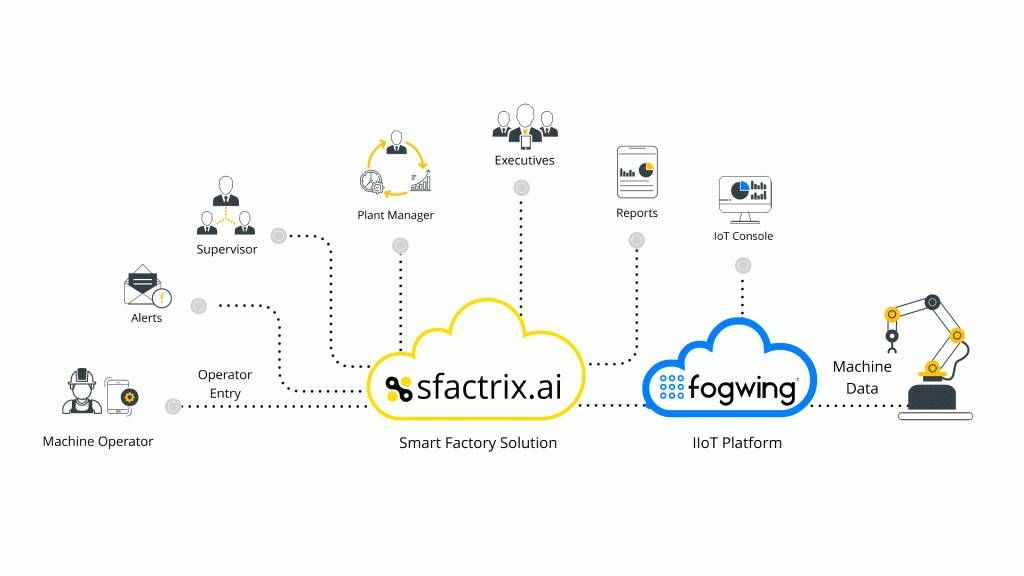

Datalogy bringing end to end next generation Digital Manufacturing solutions to small and Medium size manufacturing enterprise who are key drivers of innovation and powers supply and distribution chains to key industries to fuel overall world economy. Datalogy provide one stop value added digital manufacturing solutions incorporating best of the breed top rated SaaS , hardware/firmware products and technologies including SAP, Blueyonder, Microsoft and Fogwing.

Datalogy helps to Attain Smart Manufacturing with Industrial Cloud with Fogwing Matrix

Production Monitoring: Get Insights Anytime

Empower your production operations with production monitoring solution: Harness IoT for effortless machine monitoring, utilization, downtime tracking, and OEE optimization!

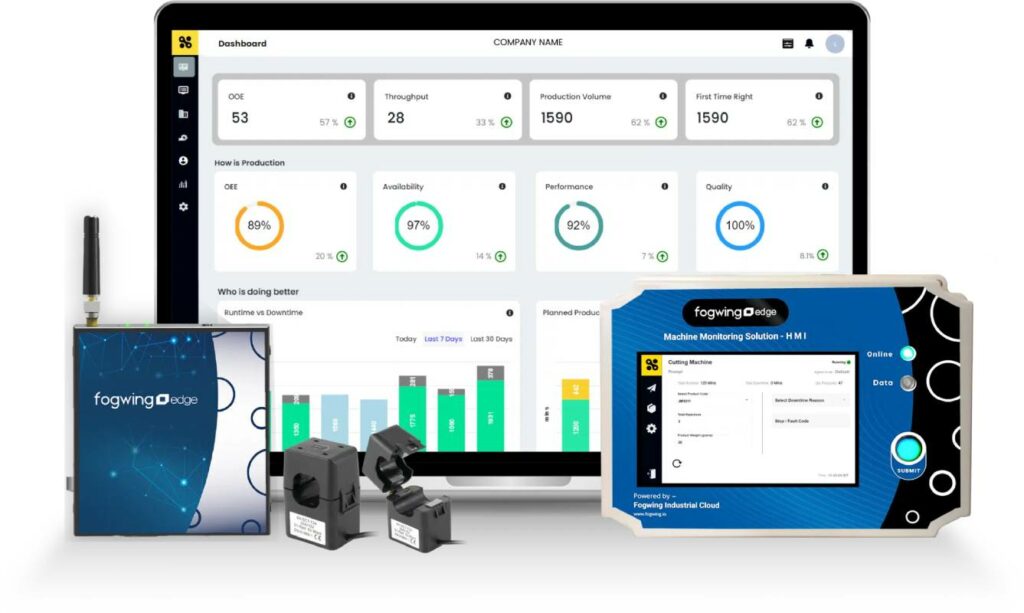

Experience Seamless Operations Monitoring

Say goodbye to manual data collection and embrace the efficiency of Fogwing Production Monitoring Software. Our solution seamlessly connects with your machines, capturing production data. Powered by the cutting-edge Fogwing Edge and HMI devices, it brings a new level of automation and intelligence to your manufacturing process.

Gain valuable insights into key performance indicators (KPIs), receive real-time downtime alerts, track loss-based metrics, analyze rejection trends, and monitor OEE metrics effortlessly.

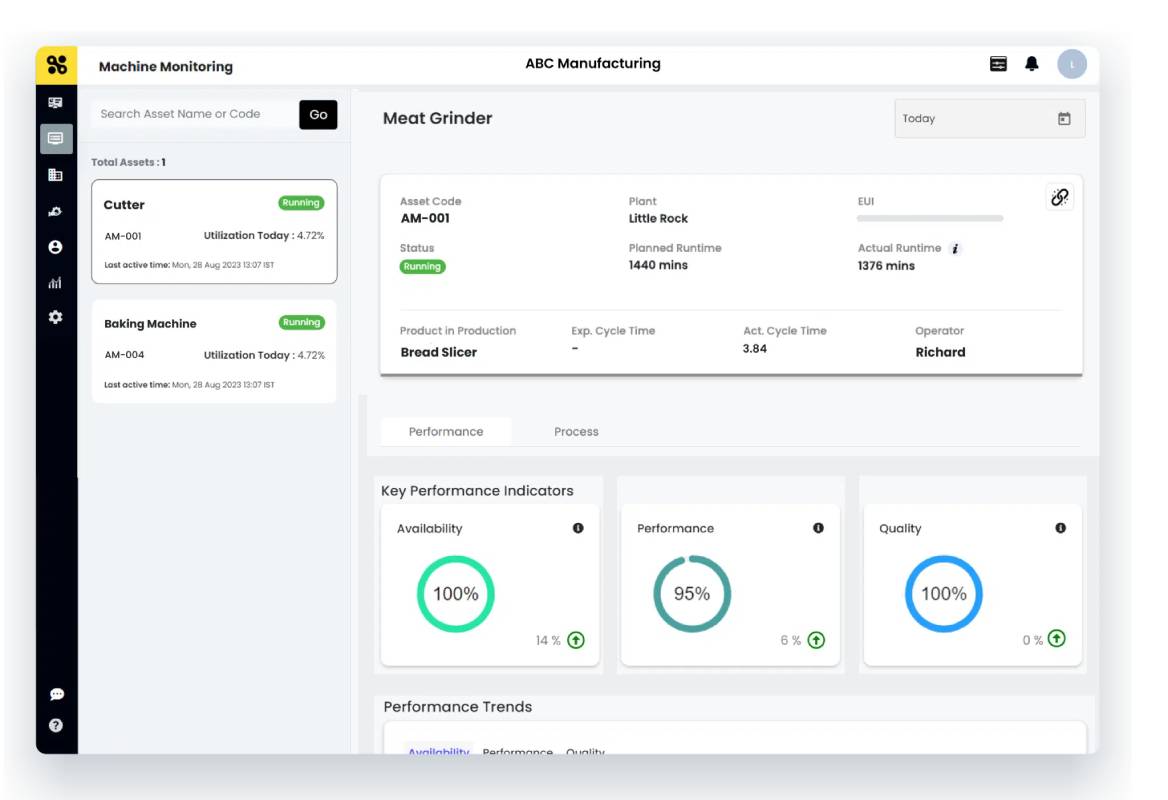

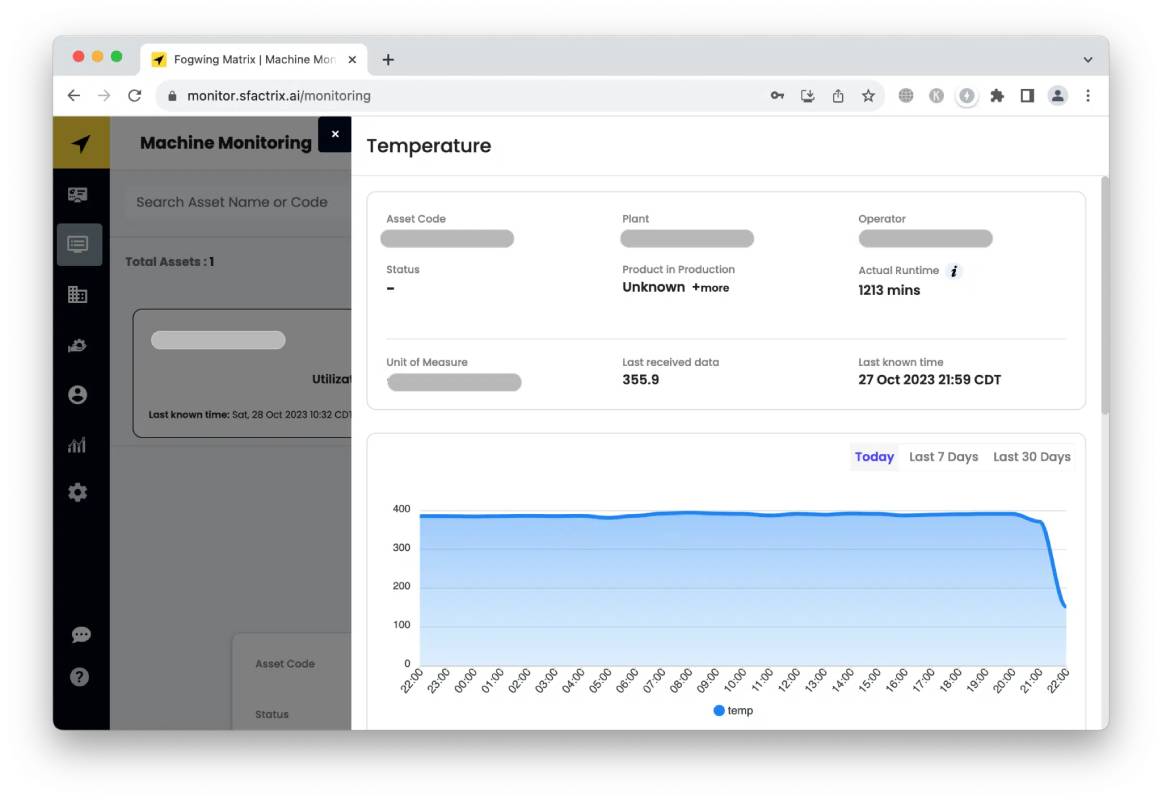

Instant Visibility through Machine Monitoring

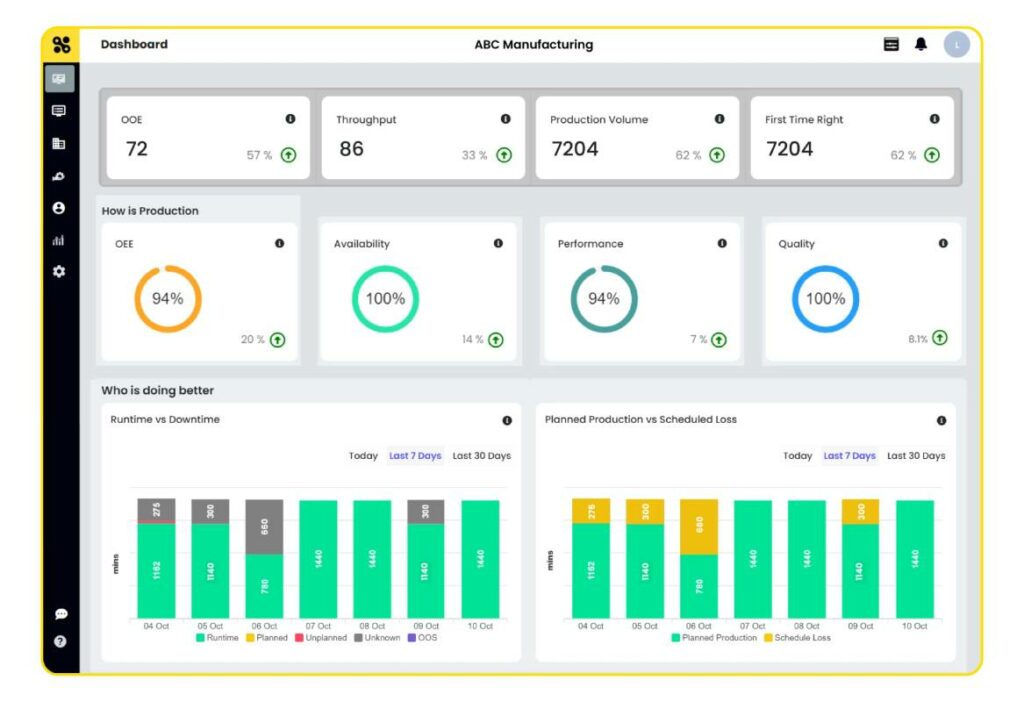

Our time-based metrics offer valuable insights that empower you to make informed decisions.

By leveraging our real-time production monitoring and time-based metrics, you can enhance your factory’s operational efficiency, reduce costs, and increase overall productivity. Don’t let time slip away—seize control of your manufacturing process and unlock the potential for accelerated success.

Metrics Includes: Runtime Vs Downtime, Planned Production Vs Schedule Loss and Efficiency.

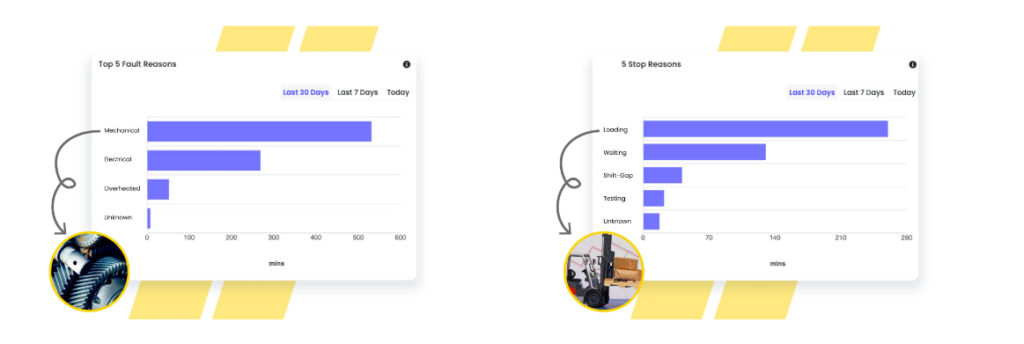

Know More About Downtime and Reasons

Unplanned Downtime

Machine breakdowns and downtime cause production delays and lead to profit Loss. Leverage Fogwing Edge IoT and HMI to capture production loss and downtime reasons for higher visibility. Take proactive steps in preventive maintenance to minimize unplanned downtime.

Planned Downtime

Our solution leverages the power of HMI to provide real-time insights into machine stoppages, helping you take control of your production processes like never before. With this system, you can make data-driven decisions to enhance machine efficiency and reduce costly downtime.

Production Process Monitoring

Fogwing Matrix offers technology-driven approach empowers manufacturers to proactively track, analyze, and optimize every facet of your process parameters. By doing so, it not only enhances product quality and consistency but also drives significant cost savings, improves operational efficiency, reduces downtime, ensures regulatory compliance, and ultimately strengthens competitiveness in today’s dynamic manufacturing landscape.

Trend Analysis: Get instant access to the production process parameters for current, trend and comparative analysis.

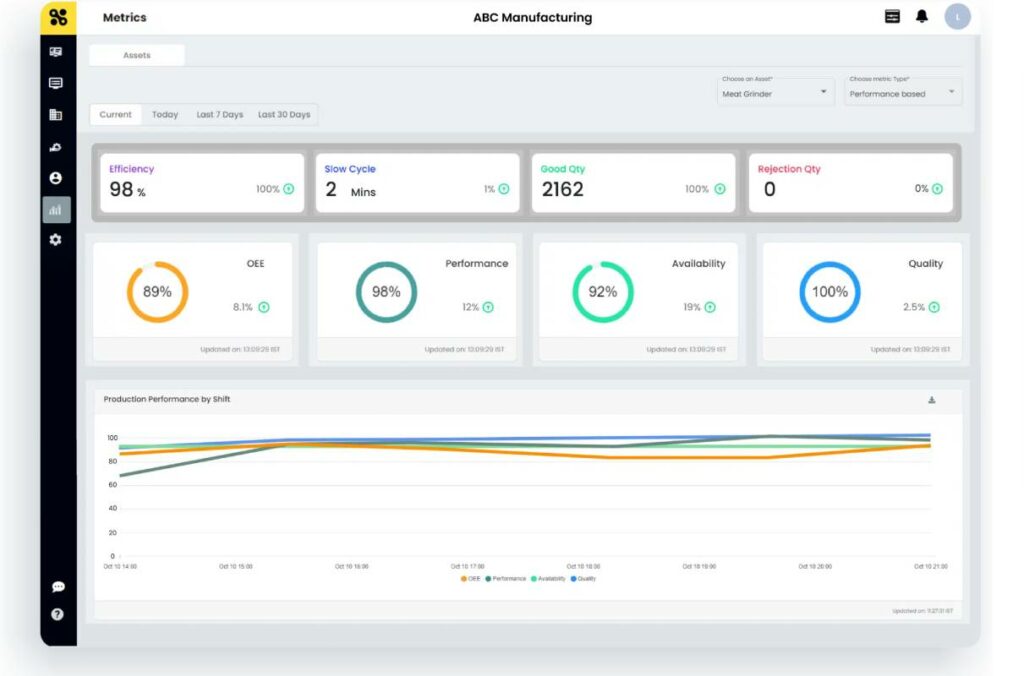

Access OEE Metrics from Anywhere

By capturing real-time data from machine availability, performance and quality, you gain instant visibility into production efficiency and wastages. Identify potential issues promptly, take immediate corrective actions, and optimize your operations like never before.

Metrics Includes: Efficiency, Slow Cycle, Production Volume and Quality Efficiency.

Embrace IoT for Automated Production Monitoring!

With the power of Fogwing IIoT, we bring you a game-changing solution that seamlessly connects your machines, controllers and PLCs, creating a network that captures valuable machine data at every step of the production line. No more guesswork or relying on outdated paper tracking methods—Our platform provides you with a comprehensive and accurate picture of your production metrics.

Edge Devices for Production Monitoring

Fogwing Edge and HMI devices are capable of connecting with any PLC, SCADA, Digital, Analog machines and Sensors to gather production data for production analysis.

READY TO CONNECT

Fogwing devices supporting to connect to any machine and sensors through RJ45, GPIO, RS232 and RS485 ports.

FIRMWARE AND SOFTWARE

Fogwing devices come with Linux OS, Fogwing Edge Agent firmware, OTAA Firmware, Node-Red, Python and OpenWRT.

INDUSTRIAL PROTOCOLS

Pre-Built workflow that helps to connect with machines to communicate in OPC-UA, Modbus, CANbus, ProfiNet protocols

WIRELESS COMMUNICATION

Fogwing edge devices are available with WIFI, 4G network connectivity. Inbuilt SIM module helps to deploy at global scale.

Why Datalogy?

Digital Transformation

Expert Skillsets

Industry Domain Expertise

Timely & Quality Delivery

Solution Accelerators

Blogs

Data-Driven Superlative Customer Experience

Consumers are increasingly seeking seamless digital experiences, particularly given that many of our daily needs can be addressed with a single click. As a result, many individuals have become accustomed to using digital, from purchasing goods online to making payments using banking apps. However, when it comes to buying insurance,

Top 9 Ways AI Is Transforming the Retail Industry

With large-scale digitalisation, it’s safe to say that AI is becoming an indispensable part of our everyday life. A prominent example of the same could be, recommendations. If you are into buying e-books on Amazon, you’ll notice you get suggestions based on your recent purchases or you might’ve noticed how

6 Steps that are Key to Data Preparation in Machine Learning

Typically, raw data cannot be used directly in predictive modelling projects like classification or regression. For algorithms to function, data must be in numbers, and statistical noise and errors must be corrected, while some algorithms impose requirements on data. Raw data, clearly, is prohibited by all means. As a result,